What are the automated solutions that Premier’s customers want the most?

Vertical Baggers, Horizontal Side-Seal units for Bagging, and Semi-Automatic Case Formers with an In-Line Case Sealer are “hot” commodities right now among our customers, according to Shawn Edwards, Premier’s National Automation Manager.

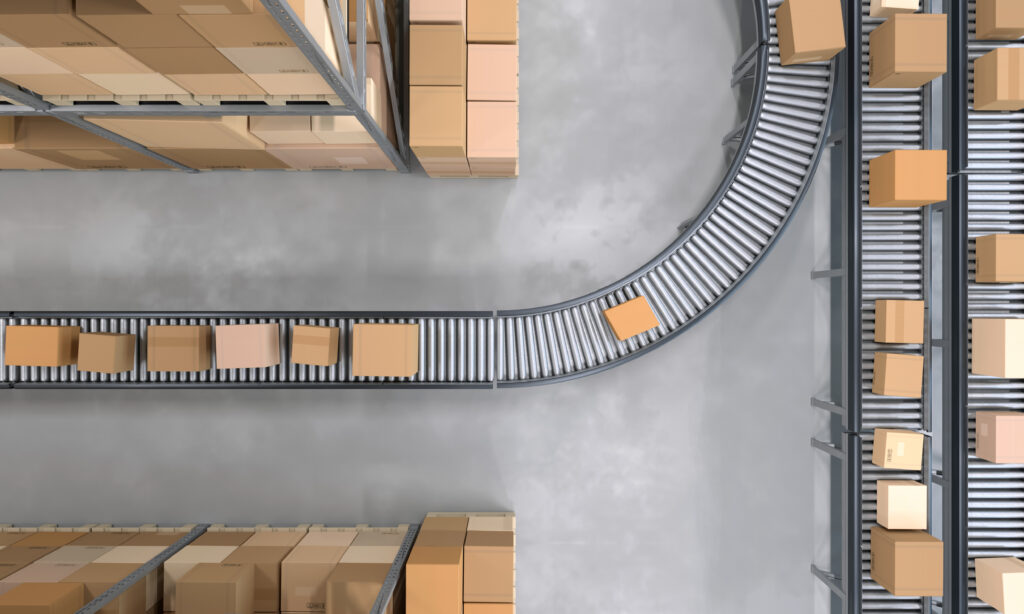

“The current market needs automation because of the small labor pool and increases in production,” said Shawn. The United States unemployment rate was a low 3.6% in June, with 6 million people unemployed. That’s a labor pool of less than the population of New York City (8.6 million) to fill all jobs across the country.

“Right-sized packaging with either corrugated cartons or poly bags can help with labor, freight, and material costs,” added Automation Specialist David Rafferty, “and this can be achieved with the equipment Shawn mentioned.”

Let’s learn more about the equipment Premier’s customers want now:

- Vertical Baggers do what the name says: Pre-made bags on a roll are presented in a vertical fashion to an operator for product placement. While a horizontal bagger will form a bag around a product, vertical baggers are better for items that are irregularly shaped, tend to roll, or can’t be easily grouped. Vertical baggers are a good solution to get away from bags on a wicket or peel-and-stick bags.

- Horizontal Side-Seal Bagging Solutions are machines that use film to produce a pouch or bag, automatically fill it with products, seal the bag on the side, and then cross-seal the ends. This flexible packaging solution can fill and seal solid, liquid, or dry products without any problems.

By creating the bag around the product, the horizontal bagger saves on material costs since there is no need for the customer to stock pre-made bags of different sizes. The machine also helps in a tight labor market since it’s estimated an automatic horizontal bagging machine can easily do the job of at least three workers who would be needed to process pre-made bags. Since the machine incorporates all stages of production, it reduces time and labor costs and makes for a faster, cheaper production process.

- Semi-Automatic Case Formers with an In-Line Case Sealer reduce the amount of manual labor needed to pre-form cases for hand-packing lines and create greater efficiency and precision. As you can see in this video, the machine forms the bottom of the case where the product is then introduced. Once the pack-out process is complete, the operator closes the top of the carton and introduces the finished carton to the top and bottom case sealer.

Hopefully this look at the hottest equipment for our customers has demonstrated how Premier can help your business become more productive while saving you money on material, time, and labor. Contact us today to find out more!