Is the fate of your packages sealed? They could come to a bad end without mechanical case sealers and the right tape.

Improperly sealed packages could come open during shipment, damaging the product inside, or not reach the customer at all. Then you face unhappy customers and the costs of returns and/or refunds.

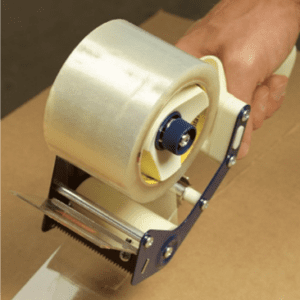

In addition, manually sealing cartons with tape guns takes more manpower and time and leaves more room for error than a mechanical case sealer. Let’s say you currently have three workers hand-packing, sealing, and shipping your product. What happens during peak, when you increase production capacity? Will you have bottlenecks? In this market, can you even find enough workers to continue manually taping your packages?

In addition, manually sealing cartons with tape guns takes more manpower and time and leaves more room for error than a mechanical case sealer. Let’s say you currently have three workers hand-packing, sealing, and shipping your product. What happens during peak, when you increase production capacity? Will you have bottlenecks? In this market, can you even find enough workers to continue manually taping your packages?

Mechanical case sealers are the answer to these challenges. They come in different versions—uniform or random; semi-automatic or fully automatic; bottom, top or side sealing; and even L clips. There truly is a case sealer for every situation and application. If you’re trying to pack and seal 200 boxes or more per day, a case sealer will offer a good return on investment (ROI). What’s more, the workers formerly using tape guns can be utilized elsewhere in your operation.

While properly sealing your cartons for shipping or storage, a case sealer can also help you avoid the over-usage of tape common with tape guns. Using less tape is better for the environment, since less becomes part of the waste stream and packages that stayed sealed only have to be shipped once, reducing carbon dioxide emissions.

What type of tape should you use with your case sealer? It depends what you’re shipping.

Water-based acrylic tape has an operating temperature range of 32 to 140 degrees, much wider than hot melt tape (45 to 120 degrees). Acrylic often works best as lightweight case sealing for cold applications, such as the food industry, or long-term storage in environments with extreme temperatures.

Hot melt tape, made from synthetic rubber, is typically used in most sealing and shipping situations. While it has poor adhesion in cold temperatures, compared to acrylic tape, hot melt generally has higher adhesion, is more flexible, and provides a more consistent seal than acrylic. It also has higher sheer strength, measured by how long a piece of steel—hanging vertically from the end of the tape—takes to slip.

When choosing a tape for your specific application, also consider grade, which refers to the thickness of the tape-backing and the level of adhesive applied. For example, higher grade tapes are thick, with a lot of adhesives, for heavy-duty sealing.

Our experts at Premier can help you find the right tape and case sealer to make your package sealing more consistent and efficient. You could say we’ll find the solution that sticks.